When it comes to home improvement, windows are often a focal point for homeowners looking to enhance both aesthetics and functionality. Among the various window materials available, uPVC (unplasticized polyvinyl chloride) has gained popularity for its remarkable durability, low maintenance, and energy efficiency. But what exactly makes uPVC windows stand out? Let’s delve into the science behind uPVC, exploring the materials and manufacturing processes that contribute to its maximum durability.

What is uPVC?

uPVC is a rigid, high-performance form of polyvinyl chloride that is free from plasticizers. This distinction is essential because plasticizers make regular PVC flexible and suitable for applications like plumbing pipes and electrical wiring. In contrast, uPVC is designed to be tough and resilient, making it perfect for structural components like window frames and doors. This rigidity means uPVC windows can endure physical stresses without bending or warping, offering long-term performance and stability, especially in fluctuating climates.

Key Materials in uPVC Windows

Polymer Composition

The backbone of uPVC is its polymer chain structure, which provides exceptional strength and resistance to environmental stressors. These polymer chains create a dense and robust material that can handle extreme weather conditions, such as heavy rain, strong winds, and intense sunlight. Unlike wooden frames that can warp or swell, uPVC maintains its shape and integrity, ensuring that your windows function effectively for years.

Additives and Stabilizers

To optimize its performance, uPVC incorporates a range of additives.

- UV Stabilizers are critical for protecting the material from harmful ultraviolet rays that can cause fading and degradation. These stabilizers ensure that the color and strength of uPVC windows remain intact over time, allowing them to retain their aesthetic appeal.

- Impact Modifiers enhance the material’s resistance to physical impacts, which is especially important in areas prone to storms or vandalism. This ensures that your windows won’t crack or shatter easily, providing safety and durability.

- Flame Retardants improve fire resistance, adding another layer of safety for homeowners. In case of fire, these additives can slow down the spread of flames, offering crucial time for evacuation and minimizing damage.

Reinforcement Materials

Many high-quality uPVC windows are designed with internal steel or aluminum reinforcements. These reinforcements provide additional strength and stability, especially important for larger window designs where the weight can be substantial. The combination of uPVC’s lightweight nature with sturdy reinforcements ensures that the frames can support larger panes of glass without compromising structural integrity.

The Manufacturing Process

The durability of uPVC windows isn’t just a result of the materials used; it’s also a product of a meticulous manufacturing process that ensures consistency and quality.

Extrusion

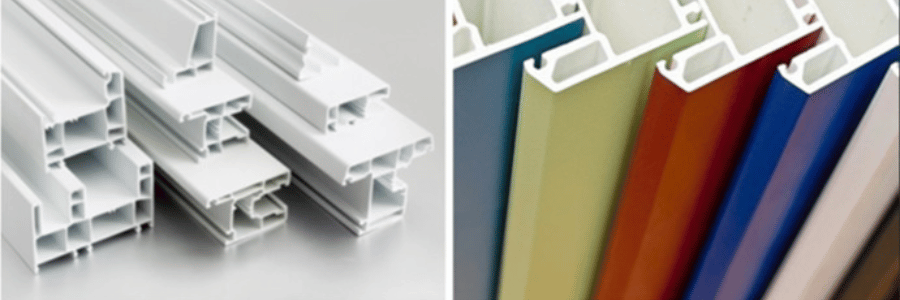

The primary manufacturing process for uPVC involves extrusion, where raw uPVC pellets are heated to a specific temperature and then forced through a die. This process shapes the material into long, continuous profiles that form the frames and sashes of windows. The precision involved in extrusion allows for uniform thickness and strength throughout each frame, minimizing weak points that could lead to failure.

Fusion Bonding

The corners of uPVC window frames are typically welded together using a process known as fusion bonding. This involves heating the edges of the frames until they melt slightly, allowing them to fuse seamlessly together. This method creates a strong, airtight joint that enhances the overall structural integrity of the window. Unlike traditional methods that may rely on screws or adhesives, fusion bonding ensures a more durable and long-lasting connection between frame components.

Surface Finishing

After extrusion and welding, uPVC frames undergo surface treatments to enhance both their appearance and durability. These treatments can include applying various finishes and textures that provide aesthetic appeal while also protecting against scratches, fading, and environmental damage. A well-finished uPVC window can look elegant while being tough enough to resist the wear and tear of daily life.

Quality Control

Rigorous quality control checks are conducted throughout the manufacturing process. These checks ensure that each window meets stringent industry standards for performance, durability, and safety. By conducting tests for thermal efficiency, structural integrity, and water resistance, manufacturers can guarantee that homeowners receive a reliable and high-quality product, reducing the risk of costly repairs or replacements in the future.

Why Choose uPVC Windows?

Low Maintenance

One of the standout features of uPVC windows is their low maintenance requirements. Unlike wooden frames, which may need regular painting, sealing, or treatment to prevent rot and warping, uPVC windows only require occasional cleaning with soap and water. This ease of care not only saves homeowners time and effort but also reduces long-term costs associated with maintenance.

Energy Efficiency

uPVC is known for its excellent insulating properties. The material effectively minimizes heat transfer, helping to keep your home warm in winter and cool in summer. This thermal efficiency can lead to significant energy savings, as homeowners can rely less on heating and cooling systems, thus lowering energy bills. With rising energy costs, uPVC windows present a financially savvy investment.

Longevity

With proper care, uPVC windows can last 30 years or more, making them a long-term investment for homeowners. Their resistance to rot, corrosion, and fading means that, unlike other materials, they won’t need frequent replacements. This longevity not only provides peace of mind but also adds value to your property over time.

Conclusion

The science behind uPVC windows showcases a blend of high-quality materials and advanced manufacturing techniques designed for maximum durability. Their resistance to extreme weather, low maintenance needs, and energy efficiency make uPVC windows an excellent choice for homeowners looking to enhance their living spaces. Whether you’re building a new home or renovating an existing one, the benefits of uPVC windows provide a durable, stylish, and energy-efficient solution. Investing in uPVC windows means choosing reliability and comfort, ensuring that your home remains beautiful and functional for years to come.

If you have any questions or want to learn more about uPVC windows, feel free to reach out!